- Available from 9:00AM - 7:00PM

Help

The business scope of this supplier's independently verified Business Registration, as licensed by relevant government agencies,allows it to manufacture goods.

15 years

China

15 years

China

Ranking reflects the supplier's financial commitment to promoting export business.

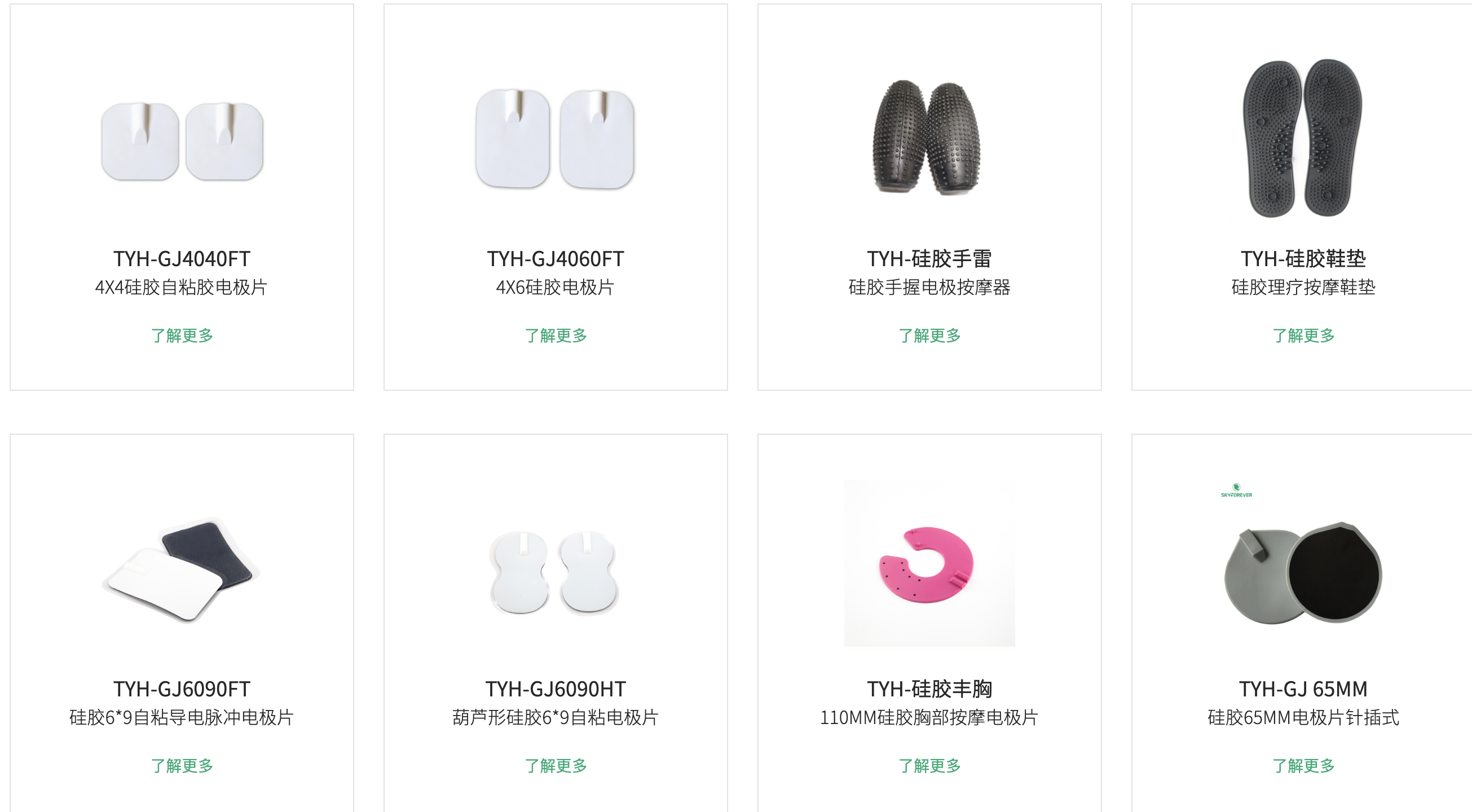

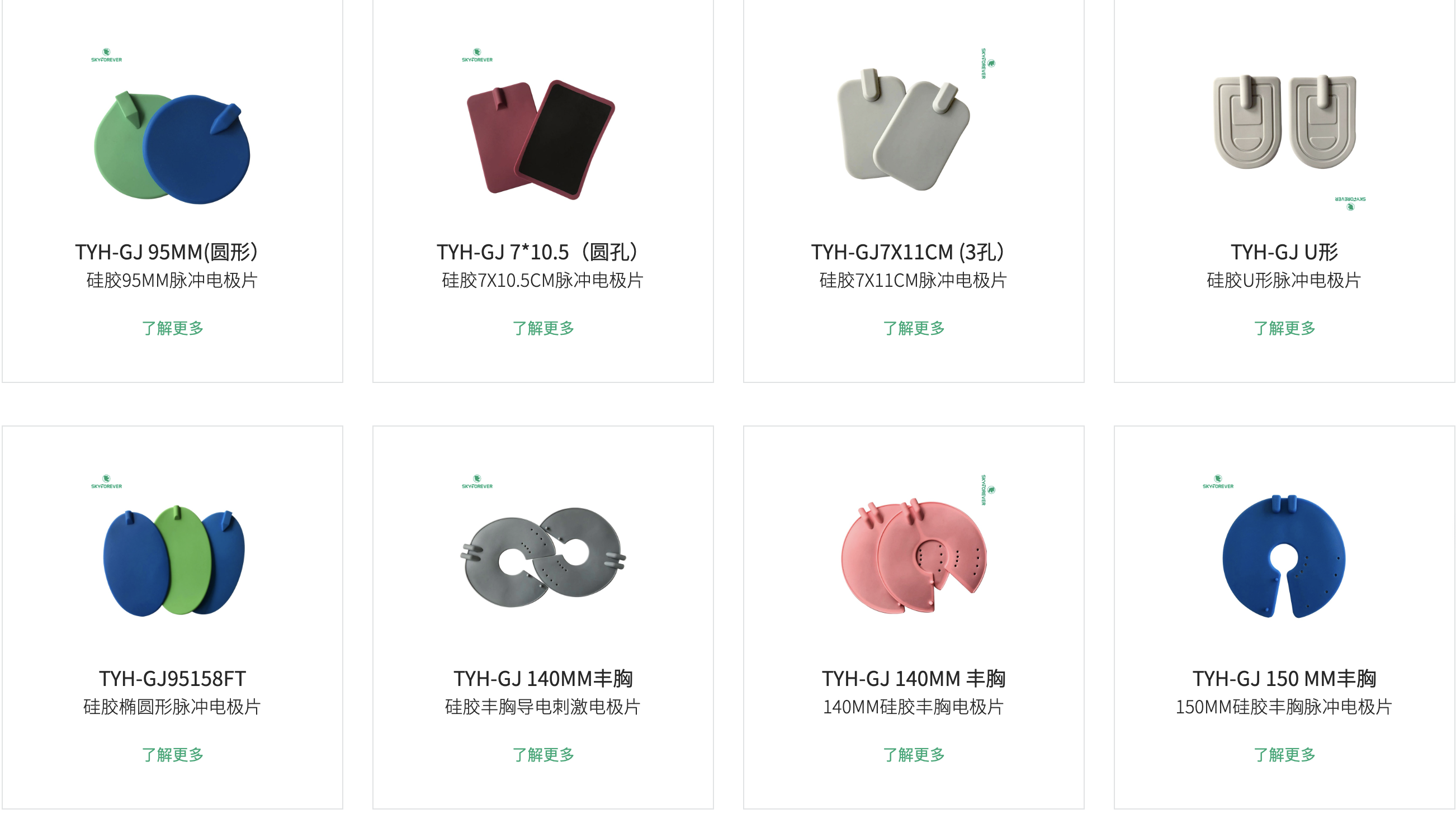

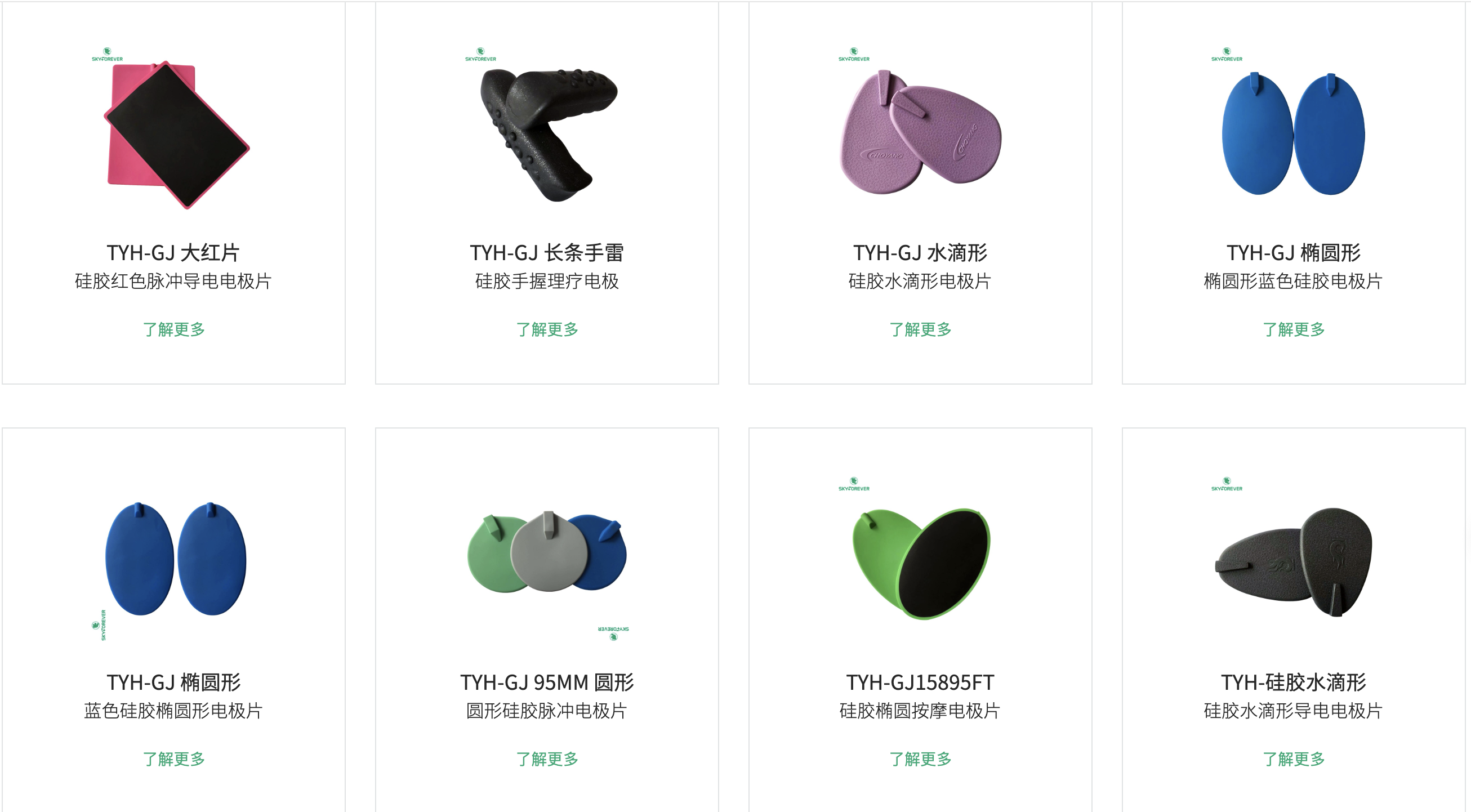

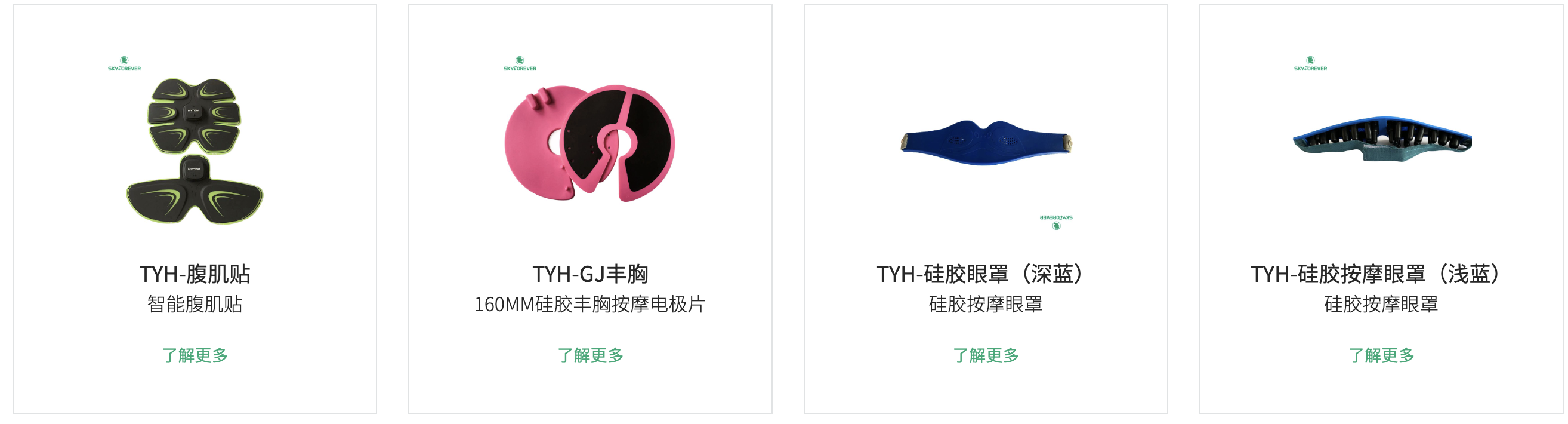

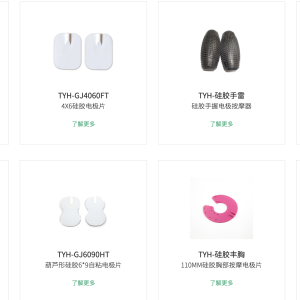

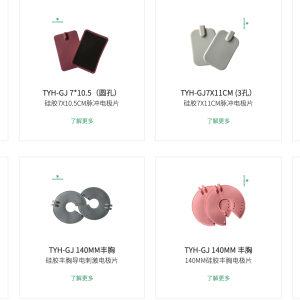

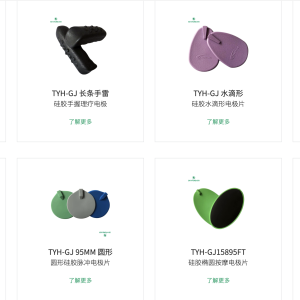

Silicone electrodes

The business scope of this supplier's independently verified Business Registration, as licensed by relevant government agencies,allows it to manufacture goods.

15 years

China

15 years

China

Ranking reflects the supplier's financial commitment to promoting export business.

$99.00

🔥 Buy More Save More!

Buy 3 items get 5% OFF

on each productBuy 6 items get 10% OFF

on each productBuy 10 items get 15% OFF

on each productHave any Questions?

Feel free to Get in touch

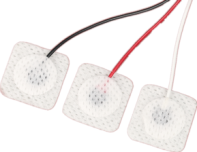

Product name

Medical silicone electrode patches

High elasticity long-lasting adhesion | Resistant to high temperature disinfection | 1,000 cycles

1. Product Overview

Material Composition:

Conductive Layer: Embedded Silver Fiber Conductive Network (Surface Resistance ≤5Ω/sq, per ASTM D257)

Base material: medical grade platinum vulcanized silicone (thickness 0.3-1.5mm adjustable, temperature resistance -50°C~250°C)

Interface: Gold-plated button/crocodile clip dual-mode design (mating life≥ 10,000 cycles)

Scope of application:

ECG monitoring, electrical stimulation therapy, bioelectric signal acquisition, adaptation defibrillator, TENS equipment, EEG machine, etc.

Applicable scenarios: operating rooms, ICUs, rehabilitation centers, and sports medicine laboratories

Second, the core advantages

1. Proprietary properties of silicone

Ultra-durable: resistant to autoclaving (121°C/30min, conductivity decay <3% after 500 cycles)

Extreme fit: 500% elongation + ergonomic molded surface, suitable for complex parts such as joints/chest and abdomen (contact impedance≤2kΩ)

Safe and non-toxic: ISO 10993 cytotoxicity/sensitization test for neonatal/burn patients

2. Customized service (stand-alone module)

Customized projects Options

Conductive mode: Unipolar (conventional monitoring), bipolar (precision signal acquisition), array (16-channel EMG monitoring)

Surface treatment: glossy (easy to clean), matte (anti-reflective), antibacterial coating (containing nano silver ions)

Thickness: 0.3 mm (high-sensitivity type), 0.8 mm (general-purpose type), 1.5 mm (anti-crush operating room type)

Sterilization packaging EO sterilization individual package (medical), non-sterilization batch packaging (scientific research), gamma sterilization (irradiation sensitive equipment adaptation)

3. Global Compliance Certification (Certification Icon Wall)

Medical certification: CE MDR Class IIb, FDA 510 (k), NMPAIII

Durability Certifications: ISO 18184 Antiviral Test, ASTM F2100 Liquid Barrier Level 4

Environmental certifications: RoHS 2.0, REACH SVHC 223, latex-free declaration

3. Technical parameter table

Project parameters

Surface resistivity ≤5Ω/sq (DC 100mA, four-point probe method)

Tensile Strength ≥8MPa (Elongation at Break 500%, ASTM D412)

Thermal Aging Performance: The hardness change after 150°C/168h ≤ 10 Shore A

Chemical Resistance Resistant to repeated rubbing with alcohol/iodophor/hydrogen peroxide (no cracking after 50 tests)

Service life: 500 cycles of high temperature sterilization / 3 years of natural aging (whichever comes first)

Reviews

There are no reviews yet.